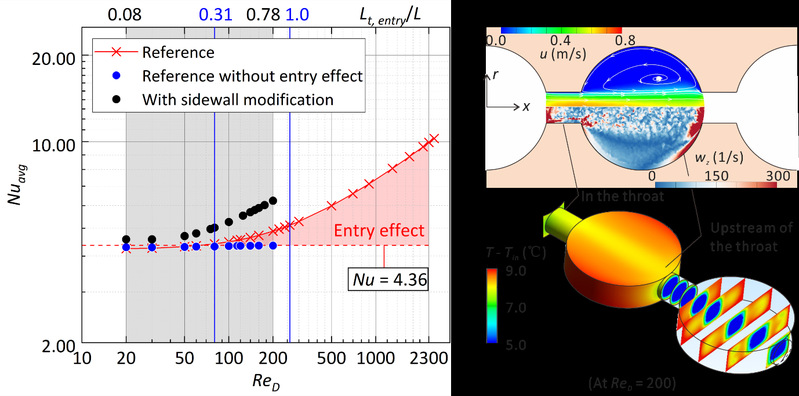

Our new work has demonstrated that sidewall modification—hemi-circular cavities arranged along a straight circular microtube embedded with a cold plate—enhances cooling, up to 40% over the reference microtube cold plate in the Reynolds number range considered.

The mechanisms have been further clarified. A short coolant passage that connects successive cavities termed a “throat” plays a crucial role in improving the cooling. Its role is twofold. The first is the enhanced cooling by a boundary layer that develops along the throat is dominant. The second is that the contraction and bifurcation of coolant flow when entering the throat cause another boundary layer to develop along the concave sidewalls. Consequently, shear stress on endwall and concave sidewall surfaces is increased, significantly elevating the local cooling.

Comparison of Nusselt number between microtube cold plates with and without sidewall modification, flow field and temperature distribution inside the cavitied microtube cold plate

This work has been published as Y. Liu, S. W. Schekman, K. Zhang, T. J. Lu, and T. Kim (2025), “Mechanisms of Enhanced Cooling by Sidewall Modification in a Microtube Cold Plate” in the ASME Journal of Heat and Mass Transfer (https://doi.org/10.1115/1.4067158) as a result of international collaboration between MLMS at NUAA, China and University of the Witwatersrand, South Africa.