Latest News

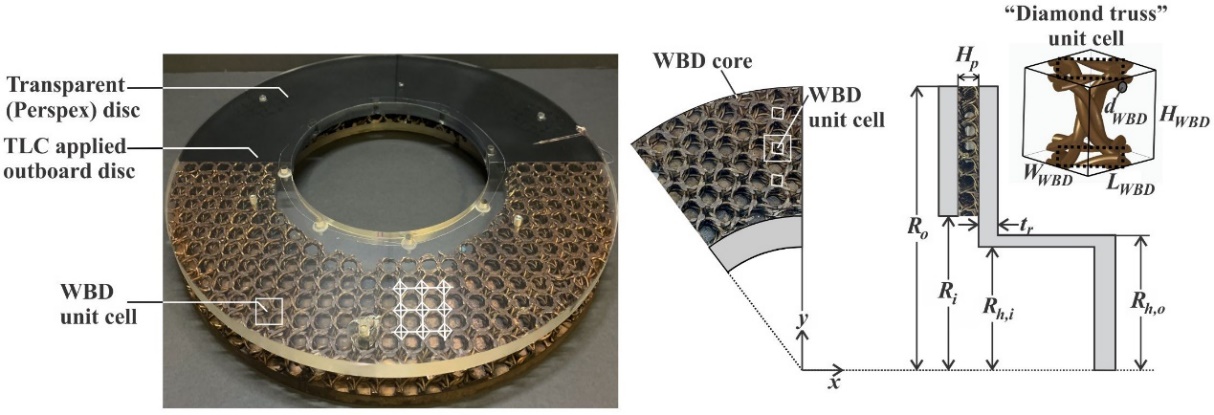

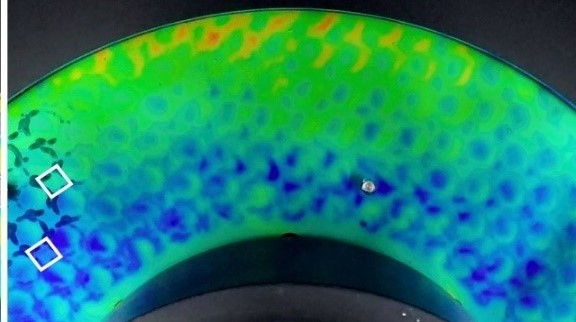

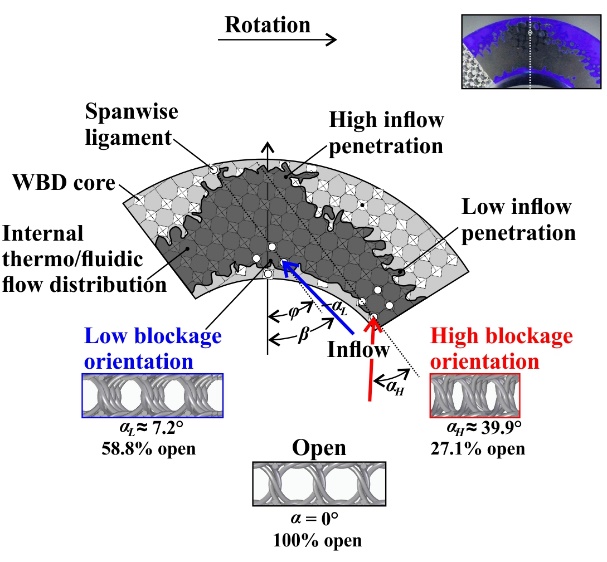

Our new work has demonstrated thermo/fluidic mechanisms governing the enhanced cooling performance of a Wire-woven bulk diamond (WBD) cored brake disc in comparison to conventional pin-finned brake discs used on heavy vehicles. The cooling advantage of the WBD core isprimarilyattributed to the combination of enlarged heat transfer surface area (both end-wall and core) and greater utilization of the larger surface due to favorable fluidic behavior developed from the WBD topology. The internal WBD core has approximately three times the surface density of the pin-finned disc which, in combination with the smaller and weaker recirculation zones, leads to more effective usage of the available core surface area for thermal dissipation. The aerodynamic anisotropy of the WBD core induced by its topological anisotropy causes a globally irregular thermo/fluidic distribution in the brake disc.

(Anisotropy of temperature distribution of a “rotating” WBD brake disc)

This work has been accepted as M.D. Atkins, F.W. Kienhöfer, K. Kang, T.J. Lu, T. Kim (2020), “Cooling mechanisms in a rotating brake disc with a Wire-woven bulk diamond (WBD) cellular core,” in ASME Journal of Thermal Science and Engineering Applicationsas a result of international collaboration between MLMS at NUAA, Nanjing, China and University of the Witwatersrand, Johannesburg, South Africa.