Elementary Prototype Production

1. Medium Scale-up of Sandwich Plate

(a) (b)

Fig 2. (a)Stamping forming (b)Laser welding

Sandwich plate is prepared by casting, laser cutting, stamping, welding and other processes. Compared with the small samples prepared in the laboratory, the size of the product sandwich plate is often larger and faces many challenges in the preparation, such as how to reduce the residual stress in the stamping process, how to stamp when the panel is thicker, how to penetrate through in the welding process and so on. The center has accumulated valuable experience in the experiment and explored a preparation process of sandwich panels. At present, it has been able to achieve the preparation of larger size sandwich panels.

2. equipment development

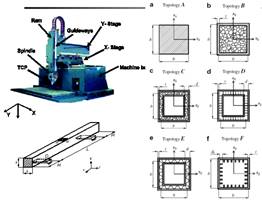

(a) (b)

Fig 3. (a) equipment development(b)Equipment preparation

Fig 3.(a) shows the improved design of the moving parts of a high-grade machine tool. In order to realize the minimum weight and maximum stiffness design of the moving parts of the machine tool, under the premise of considering the application, through theoretical analysis and finite element calculation to compare different topological structures, an optimization model is established to realize the optimal design of the ultra-light metal tool box, such as Figure 3.(b). In this process, our center explored the related process from equipment improvement to equipment preparation.