Aerospace Life Support Materials&Structures

The life support system of aerospace is the key to all activities such as deep space exploration, space travel, space station experiment and low altitude extreme flight in the future. Through the design and development of multi-functional and integrated new materials and structures (anti-impact, fire prevention, anti-static, anti-radiation, anti-interference, heat preservation and ventilation), efforts are made to provide safe, reliable and comfortable working and living environment for personnel engaged in aerospace activities.

In view of the needs of Shenzhou series spacecraft re-entry capsule, we have successfullydeveloped "closed cell aluminum foam" and "gradient pore structure closed cell aluminum foam" lightweight energy absorber (SZ-5 to SZ-9 progress). Accurate gradient control theory and fabrication technology of pore structure are proposed for the first time in the world. The theory and calculation model of material mechanical properties under impact conditions are established and perfected. The optimal design method of gradient pore structure is proposed.

The direction of liquid-saturated biological porous materials aims at the major needs of life support of China's aerospace industry and the forefront of international science and technology, and focuses on the research on the application of liquid-saturated biological porous materials in biomedical engineering and medical detection. Focusing on some key scientific issues, I focused on the study of material transfer and thermal and mechanical properties of hydrogel materials and paper-based multi-porous materials. I have accumulated rich research experience in the field of instant diagnosis and tissue engineering based on the direction of liquid-saturated biological porous materials and devoted myself to the research of biomechanics and biomaterials. Through the combination of theory, experiment and numerical value, the chemical, thermal and mechanical coupling phenomena in biological systems are studied and explained with liquid-saturatedbiological porous materials as the carrier. From biomechanics, biological heat transfer, theoretical system, biomedical engineering, such as for aerospace life support system to provide constructive and fundamental solution strategy, and through the science, engineering, biology and medicine close cross disciplines such as cooperation, use of philosophy, the principle and method of natural science and engineering, from multi-angle and multi-level study life in the body of porous structure and functions and mutual relations, aimed at challenging frontier science problem, create effective tools can explain these problems, make new contribution to aerospace and health.

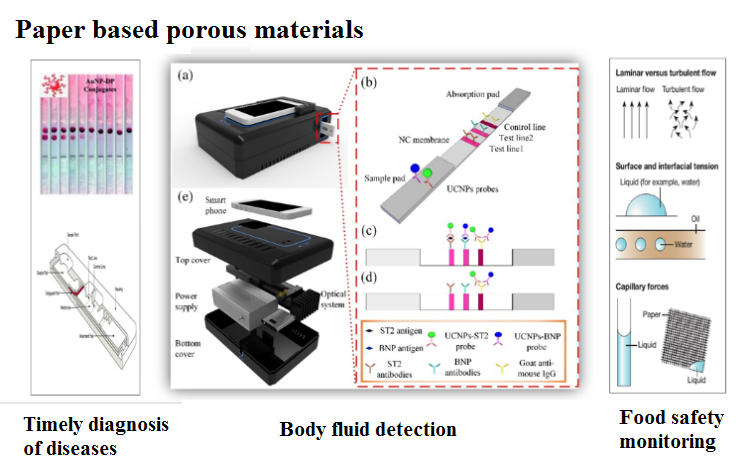

Paper-based porous materials have good liquid lateral flow properties and have broad application prospects in the field of instant diagnosis. Around the paper-based porous material, the development of real-time diagnostic technology and platform was carried out, using a combination of numerical simulation and experimental platform (side-flow test paper, paper-based electrochemical sensor, paper-based microfluidic technology and nanoscience). For members of the aviation aerospace fluid food safety detection and space environment in the process of rapid detection of sample pretreatment, separation and capture of target detection and signal collection, transformation, and analysis of major problems in science and technology, developed a series of qualitative, semi-quantitative and quantitative detection of product prototype, and reveals its theoretical law.

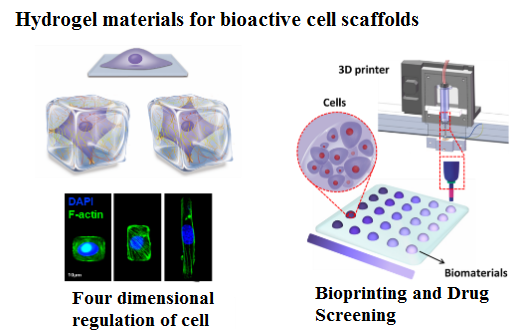

We are committed to the development of bioactive scaffold material hydrogels and aerospace biomedical applications. Hydrogel material can simulate the matrix of cell growth and development in vivo due to its good diffusion performance and excellent biological compatibility brought by its porous structure. In combination with new hydrogel materials and advanced micro-nano biological manufacturing technology, 3d micro-environment for cell growth and differentiation was constructed and regulated, 3d micro-environment characterization technology was developed, and theoretical model of cell-hydrogel interaction was established. On the basis of the research on the mechanical properties of hydrogels, the regulation rules and mechanism of microenvironmental factors such as mechanics, electricity and heat on cell behavior were explored. Based on the hydrogel 4D bio-printing technology, it can be used to construct functional engineered tissue regeneration cell scaffolds, myocardium and nerve tissue, providing theoretical reference and solutions for in vivo tissue regeneration, in vitro pathological mechanism and drug screening research.

Next Page:Multifunctional Optimization and Collaborative Design