| Lightweight Material |

| Design&Manufacture |

| Performance Testing |

| Static mechanical properties |

| Dynamic Mechanical Properties |

| Nonlinear Vibration |

| Vibro-acoustic Properties |

| Flow and Heat Transfer Properties |

| Electromagnetic Properties |

| Bioinspired engineering and biomechanics |

| Multifunctional Optimization and Collaborative Design |

Dynamic Mechanical Properties

1、Research on the anti-penetration performance of lattice-ceramic composite

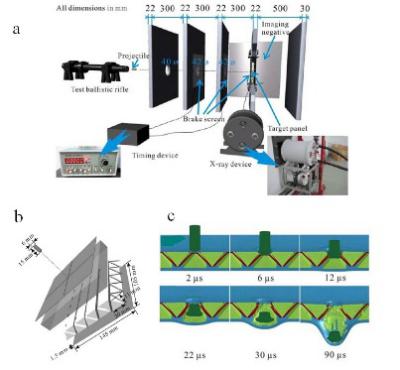

The new generation anti-penetration armor is rather urgently needed for military vehicles. We have come up with a concept of metal lattice-ceramic composite sandwich structure which can combine the porous lattice structure, ceramic materials with epoxy resin material. By means of experiment or numerical simulation, we can cast research on the structural dynamic response for different-shaped vertical/inclined bullet. Our research focus on the anti-penetration limit speed, energy absorption rate and the destruction mechanism, and by comparing the energy absorption percentage of each materials, we can give optimization on the size of the structure.

Figure 1 (a)experiment on penetration; (b) lattice-ceramic composite structure; (c)numerical simulation on penetration

2、Research on the anti-detonation performance of metal sandwich structure

Aiming at improve the anti-detonation performance of vehicles and protect people, we have designed the sandwich armor of which the core is made from stainless metal corrugate panel, square opening honeycomb, tubular cross and corrugate-foam composite structures. We have cast experiment on the structure’s anti-detonation performance under the 2kg TNT explosive circumstances. The deformation characteristics of several structures are analyzed and the rear-panel displacement and accelerated velocity are analyzed. This can provide important reference for engineering.

3、Impact experiment with foam bullet

Foam aluminum bullet impact is a great technique for impact experiment on the dynamic statistics of structures. By means of the impact facilities and high speed photograph, we can easily investigate the dynamic properties of s small scale sandwich panel, watch its destruction mode and principle.

4、Dynamic compression properties on corrugate foam-filled composite structure

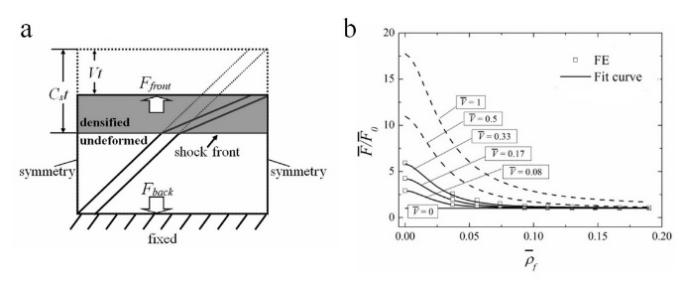

In order to watch the abilities of corrugate-foam composite structure under different impact speed, we have found some typical mode: quasi-static mode, excessive mode and shock wave mode. By momentum, we can give the counter-acting force of the leading panel. We have also found the mutual condition of the impact speed: with speed increasing , the strengthen of inertial effect is obvious, but the restrictive effect of foam is decreasing.

Figure 2 (a) foam-corrugate composite structure dynamic model; (b)influence of impact speed and relative foam density on composite effect

5、Dynamic compression properties on the gradient foam

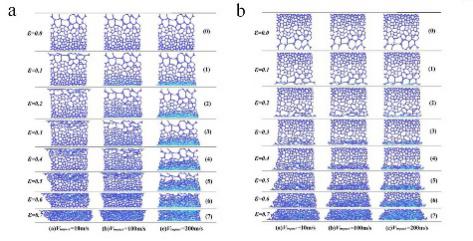

By the Ct scan of close cell foam aluminum, we have established the FEA model of 2D gradient foam metal microscope material.the inhomogeneity of the shape or distribution of cell holes, the gradient distribution of the size of cell holes and the wall thickness in its height direction are considered. We have also analyzed the deformation of gradient foam metal material under the dynamic compression process, the path way and change features of stress, analyzed the energy absorption principles and properties of foam metal.

Figure 3 dynamic compression deformation image of gradient foam metal under the gradient direction: (a) positive gradient; (b)negative gradient

Next page:Nonlinear Vibration